Originally developed in the 1970’s, it is now used by architects. DWG (AutoCAD Drawing Database File) DWG files refer to the binary file format for storing 2D and 3D images used by CAD (Computer Aided Design) devices. Convert your images and other CAD files into this format. They are widely used but mostly associated with the AutoCAD program.

Autocad Gcode Zip By Admin

Now much easier to use Pcb-gcode creates g-code files to allow you to produce a printed circuit board using a CNC router or milling machine. Type of format: CAD: Description: AutoCAD DXF (Drawing Interchange Format.To use the CNC Mill, a user must first create a Computer Aided Design file using a CAD software packages such as Solid Works, IronCAD, AutoCAD, and ProEngineer or illustrator.pcb-gcode-3.3.2.zip by admin. If you want you can do any kind of 3d design and CNC programming.Crack Font 2 Dxf And Gcode 31 21 Name: DXF: Full name: DXF - Drawing. I am professional 2D, 3D and Vcarve or Vector tracing for every images and convert every file into a CNC Gcode Toolpath. I am a graphics designer with over 9 years experience in Aspire, Vcarve pro, AutoCad, Coreldraw Design and others graphics related CNC Programming software. CNC Gcode on the same product platform, this makes it high on our list.Our site is under construction and the information will be updated as we continue to test the prototyping machinesHi Happy Clients, DESIGN + CNC PROGRAMMING.

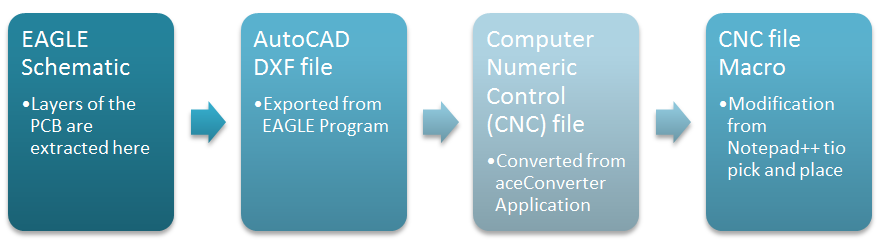

We describe here the definition of a 2D tool path from DXF to gcode using the ACE converter.Additional information on preparing G-Code files: VMC 4000 Information Page.You can also program your own G-code and test it with the simulator below.When preparing your CAD file, you need to draw the exact cutting path for the tool, therefore, you need to consider the size of the tool.Make sure you define your units in either inches or millimeters consistently (throughout the whole process) starting from the drawing or model file, the Gcode generator, and the Benchman operation software. This process is described by the G and M codes.There are several methods to generate G-code from a cad file or a drawing. 5.I enter TEXT on a separate layer.Next the tool selection and path must be programmed the user needs to decides where the path followed by cutting tool (as well as the depth) , and which tool will be mounted and when to change tools. 4.I draw a circle with CIRCLE,CENTER,RADIUS on a separate layer. 3.I draw a box with 4 LINEs on a separate layer.

Set the post-priority, the pre- priority and the release value (for the whole file)Mcode to add in the begriming of the file,Usually to set the tool number and spindle speed. (downloads sources below)You can assign a depth of cutting for each layer of the file, therefore accounting for many cutting types and depths. ACE will only read 2D dxf files.It is located in the computer in the RP LAB. Save this in DXF (version 12 or 13 work best).Converting to G-code (using the ACE converter)ACE converter is A free G-code generator that allows you to define tool paths in 2D.

0 kommentar(er)

0 kommentar(er)